NBC News: “Georgia student, son of 2 first responders, creates lifesaving COVID-19 equipment”

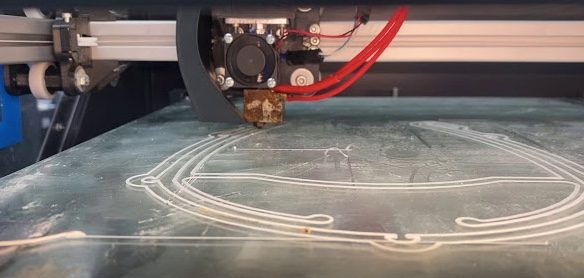

Friends and colleagues, we hope you will enjoy this inspiring story of innovation and collaboration that is helping keep our frontline healthcare professionals safe during this time of desperate need. “I saw nothing better I could do to give back to people like my mom, my dad — who have been working in emergency services…