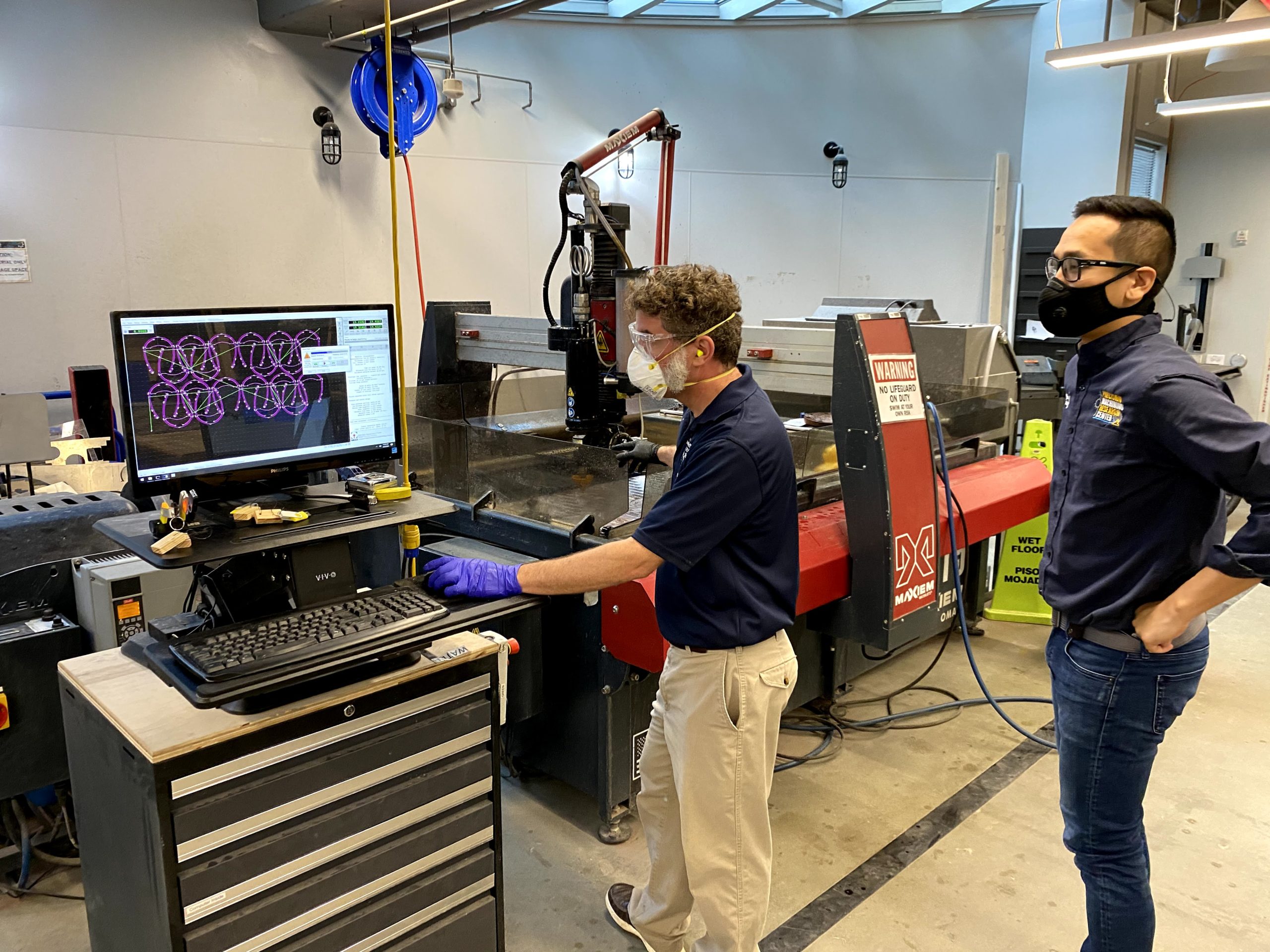

In mid-March 2020, the shortage of personal protective equipment for healthcare providers responding to the COVID-19 outbreak had become a national emergency. By the time the University System of Georgia suspended on-campus instruction and asked students to depart campus by March 13 in response to rapidly increasing numbers of COVID-19 cases, Christopher Saldana, Ph.D., associate professor of manufacturing at Georgia Tech and his mechanical engineering students and colleagues were already working on challenges and solutions for desperately needed protective personal equipment (PPE) for frontline healthcare workers.

Image credit: GT Research Horizons

The very same weekend, Christopher and his team produced their first set of PPE face shield prototypes and began gathering feedback from clinicians.

What the team needed next was a scalable, final design capable of transitioning to large scale manufacturing to meet the end users’ urgent needs. Thanks to the close knit medtech innovation ecosystem in Georgia, and Atlanta in particular, Sherry Farrugia and Joanna Newton, MD, connected Christoper and his team with GCMI.

Sherry Farrugia is Chief Operating and Strategy Office, Children’s Healthcare of Atlanta Pediatric Technology Center. Joanna Newton, MD, is Pediatric Oncologist/Hematologist, Aflac Cancer and Blood Disorder Center of Children’s Healthcare of Atlanta and Assistant Professor of Pediatrics, Emory University School of Medicine.

GCMI marketing partner Write2Market spoke with Chris in early April while he was in the lab working on designs and prototypes for protection of clinicians during intubation procedures.

Designing for large scale manufacturing, in a BIG hurry

Starting Monday, March 16, the team collaboration produced the final designs including documentation and regulation considerations to enable manufacturing partners to produce the face shields and begin distribution to the front line providers and hospitals.

“Generating a final solution to a desperately needed medical product was quite a challenge,” Chris said. “We went into an ‘all hands on deck’ startup mode to rapidly design, prototype and iterate. We used our fabrication facility to produce prototypes. GCMI documented clinical feedback, functionality and traceable document specificity. It is immensely important to understand the use case in the hospital setting as well as requirements for large scale manufacturing. GCMI excels in these areas. They helped guide our prototyping because manufacturers need specific details on manufacturing allowances and tolerances to deliver the product the frontline clinicians need.”

“Generating a final solution to a desperately needed medical product was quite a challenge,” Chris said. “We went into an ‘all hands on deck’ startup mode to rapidly design, prototype and iterate. We used our fabrication facility to produce prototypes. GCMI documented clinical feedback, functionality and traceable document specificity. It is immensely important to understand the use case in the hospital setting as well as requirements for large scale manufacturing. GCMI excels in these areas. They helped guide our prototyping because manufacturers need specific details on manufacturing allowances and tolerances to deliver the product the frontline clinicians need.”

Key factors in collaboration efficiency

Proximity, proficiency and willingness to dive straight in were key elements to efficiency in this large group collaboration.

“GCMI is literally a ten minute walk from our innovation studio at Georgia Tech,” Chris said. “If we need an in person conversation, if we need to examine materials or prototypes we can be there in a fraction of the time it would take for us to convene with other partners or have them come up to our space. They also have proficiency in delivering products to markets including working with frontline hospitals and health systems where these shields will be put to use protecting the professionals treating patients.”

What research and engineering teams can learn from Professor Saldana’s experience

“A manufacturing engineer will show a mechanical engineer a completely different environment from the lab,” Chris said. “Manufacturing and its systems have changed, yet the effects of the PPE shortage on the healthcare workforce is an intensely immediate problem. Working with the right folks like Dr. Newton and GCMI helped us understand and solve the problem faster, iterating to a final design and delivering to manufacturers in three days from the moment we started working with them.”

“For those researchers and engineers working on innovations with medical applications, understand your situation is different from what you’re used to. Address design processes to meet needs and solve problems both now and in the future. Get stakeholders involved immediately to understand physical problems in manufacturing that must be solved to address the need.

“Your initial solution may not be ideal for the use case based on voice of customer or clinical input. Be prepared to iterate and produce alternative designs swiftly. You want to have more than one horse in the race. Creating multiple mature prototypes, much like Apple does with their new products, will make for a more functional, manufacturable product in the end.

“What allowances need to be made on the product and manufacturing sides? Answering these questions at the conceptual design phase is beneficial and accelerates time to solution and market entry.”

Update – As of Tuesday, April 7th, more than 250,000 PPE face shields have been (or will be) produced and delivered to frontline hospitals and their clinicians. GCMI would like to thank all of our partners including the CHOA Pediatric Technology Center, Coca-Cola, Emory School of Medicine, Delta Flight Products, Siemens and ExxonMobil.

Update – As of Tuesday, April 7th, more than 250,000 PPE face shields have been (or will be) produced and delivered to frontline hospitals and their clinicians. GCMI would like to thank all of our partners including the CHOA Pediatric Technology Center, Coca-Cola, Emory School of Medicine, Delta Flight Products, Siemens and ExxonMobil.

Contact GCMI to discuss your medtech innovation’s pathway to care

GCMI and the whole of the medtech community in the region is very closely knit. If you want to discuss your ideas and designs, especially those that can positively impact front line healthcare provider needs and patients, anyone on the GCMI team can point you in the right direction.

Email info@gcmiatl.org to get started.